Revolutionizing production efficiency with advanced 3D printing technology

How 3D printing is transforming the production of rubber hose molds for the automotive industry

Cut lead time from weeks to days with high-performance 3D printed molds, enabling fast, flexible, and cost-effective small-batch production.

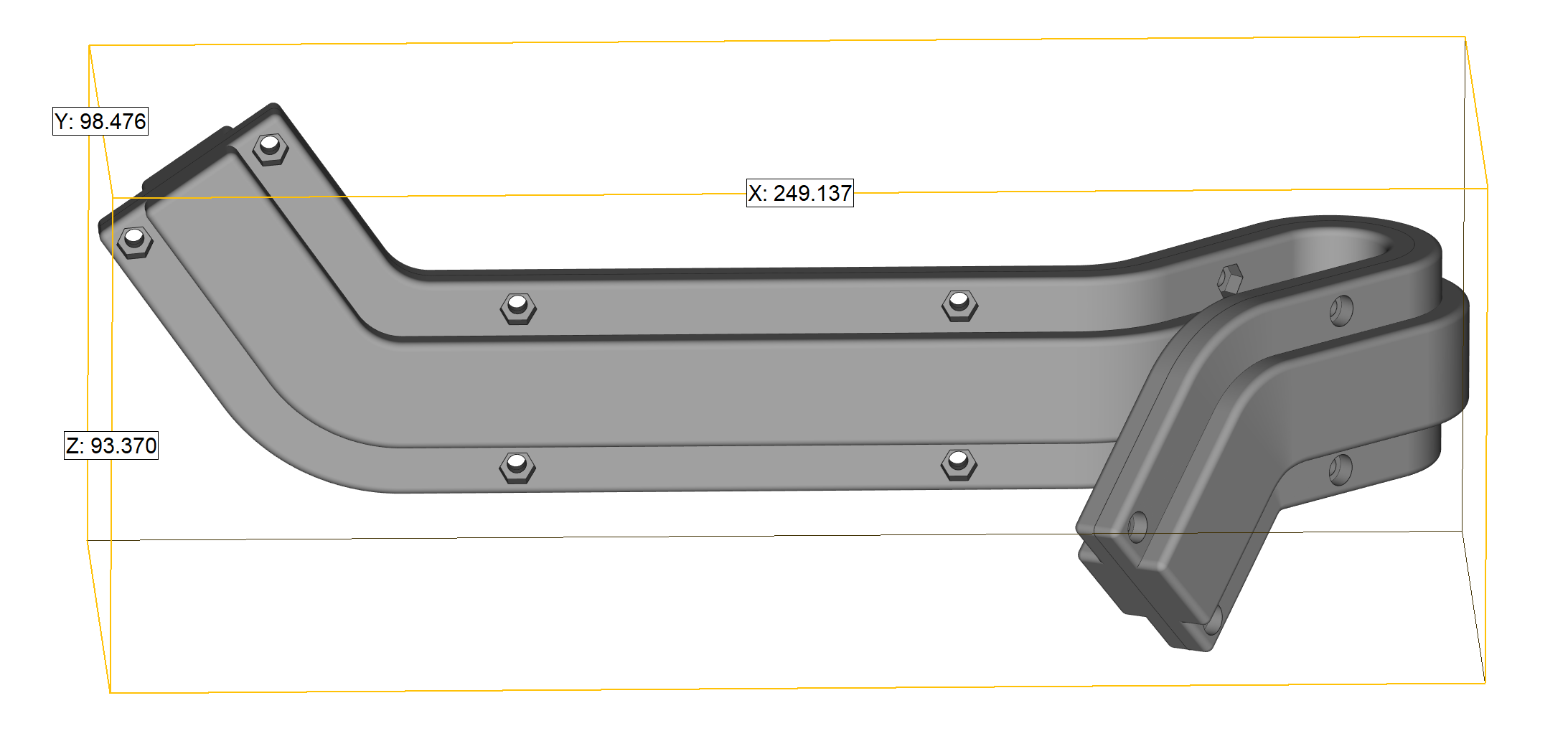

Create intricate mold designs with complex internal channels and cooling systems that would be impossible to manufacture using traditional methods.

Significantly reduce tooling costs and material waste while maintaining high quality and precision for small to medium production runs.

Quantifiable improvements in manufacturing efficiency and performance

Reduction in mold production time

Cost savings compared to traditional manufacturing

Local dimensional accuracy within ±0.1 mm

Reduction in material waste

How a leading automotive manufacturer transformed their production process

A major automotive parts supplier needed to produce complex rubber hose molds with intricate internal geometries while reducing production time and costs. Traditional manufacturing methods were unable to meet these requirements efficiently.

Using INTAMSYS high-temperature 3D printing technology, we developed a custom manufacturing process that allowed for the direct production of functional molds with optimized cooling channels and complex geometries.

The client achieved a 80% reduction in production time, 56% cost savings, and significantly improved product quality with enhanced consistency in the final rubber hoses.

"The 3D printed molds have completely transformed our production process. We've not only reduced costs and time-to-market but also improved the quality and consistency of our rubber hoses. This technology has given us a significant competitive advantage."

Our industrial-grade 3D printer delivers exceptional performance for demanding applications with superior reliability and part quality.

PEI 1010 has a higher thermal deformation temperature than PEI 9085, reaching 200°C. PEI is an amorphous, high-performance polymer that combines excellent thermal properties, dimensional stability, inherent flame retardancy, and good chemical resistance.