60 min

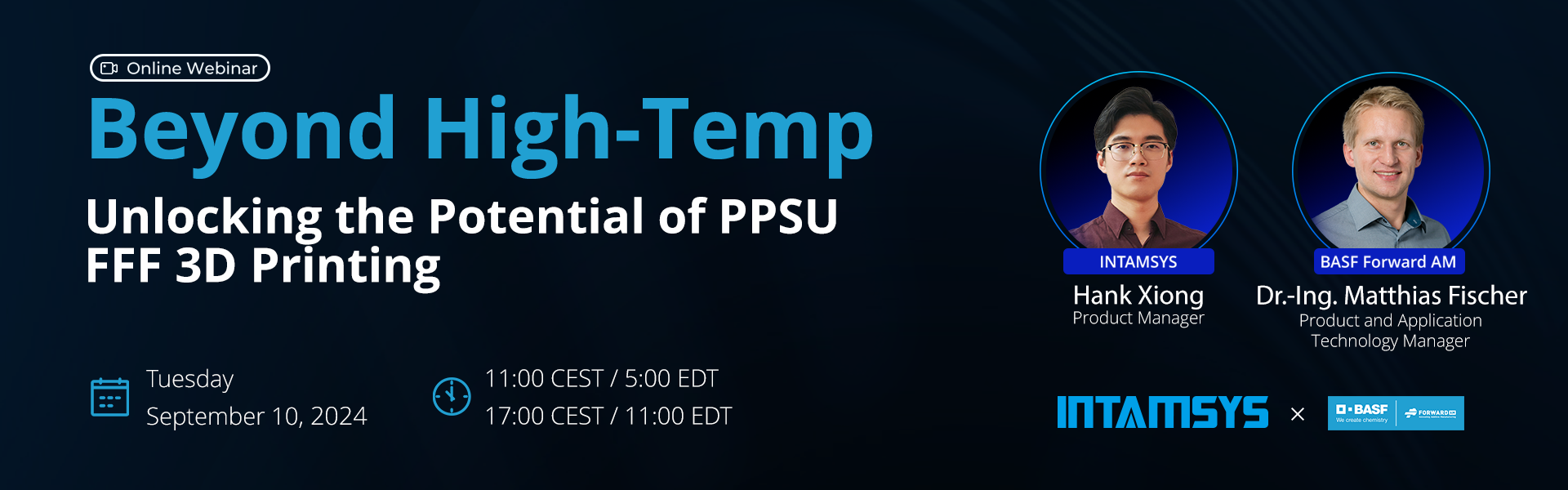

Join us for an insightful webinar titled "Beyond High-Temp: Unlocking the Potential of PPSU FFF 3D Printing" on September 10th, 2024. PPSU is known for its outstanding thermal and chemical resistance, making it an alternative for PEI applications in aerospace and railway industries.

This event is designed for professionals and enthusiasts in the 3D printing industry who are keen to explore the advanced capabilities of PPSU material in FFF 3D printing.

Our expert speakers from BASF and INTAMSYS will provide a comprehensive overview of PPSU's properties, Additionally, attendees will gain practical insights into FFF 3D printing with PPSU, and see real-world applications and success stories.

Product and Application Technology Manager

Dr.-Ing. Matthias Fischer is a Product and Application Technology Manager at Forward AM. He gained his first experience in 3D printing during a student assistant job in 2010. After his Master's studies, with a focus on polymer processing, Mr. Fischer worked at the Direct Manufacturing Research Center (DMRC) at Paderborn University as a scientific employee. Here, he was responsible for projects related to Fused Filament Fabrication.

Product Manager

Hank Xiong is a Product Manager at INTAMSYS. He cumulated early experience in multi-material (polymer and concrete) large-scale robotic FFF/FDM 3D printing, which focused on printing process R&D and project application management at Fab-Union cooperating with Tongji University. With an Engineering MSc background from the University College London and an interm CEng registration, Hank had worked in industrial software development and additive manufacturing in construction and manufacturing industries.

This high-performance thermoplastic polymer excels in chemical stability, wear resistance, and mechanical strength, making it ideal for aerospace, automotive, and medical applications. Dive into the whitepaper to explore how PEEK's unique properties and advanced 3D printing technologies are revolutionizing the manufacturing landscape.

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy